Roof Coating Systems – Approvals, Building Codes, Ratings, and Standards Explained

We have often seen acronyms and numbers on roofing products for submittals but what and who do these acronyms represent? That can be easily answered with some history of roofing products, specifically liquid or fluid applied roof coating systems. In the past one of the things that has been overlooked in the roof coating industry, and the roof maintenance industry, had been any kind of testing and approvals. In the past these types of products were looked upon as a band aid and had little regulation.

Western Colloid and other roof coating industry pioneers have spearheaded efforts over the last 30 years to seek proper approvals and standards. Building owners and specifiers now have the confidence that they can use products that have been tested, with the same rigorous methods that single-ply’s, modified bitumen, built-up roofs, etc., have beenSo how is the industry evaluated? Let’s start with FM Global

FM is Factory Mutual Global, one of the largest insurance carriers in the world. FM Global was founded in 1835. FM Global is a Fortune 500 company, they insure over $10 trillion worth of properties globally, in 130 countries with 6,000 employees worldwide. Their research campus in W. Gloucester, RI is 1600 acres. It is the most sophisticated center for advancing the science of property loss prevention.

There are other testing and evaluating agency’s such as Underwriters Laboratories, Miami-Dade, ICC-ES, CRRC, but FM Global is the gold standard.

One of the reasons FM has gone beyond their insurance capabilities is because of the nature of the insurance claims, and because nobody was testing roofs to their comfort level. They started doing testing decades ago, and now they’re not just looked at as a testing center. Whether you are insured by FM Global or not, the fact that you pass an FM standard is the highest form of approval. The testing portion of it kind of stands alone when necessary. You don’t necessarily have to have an FM insured building to have an FM approved roof.

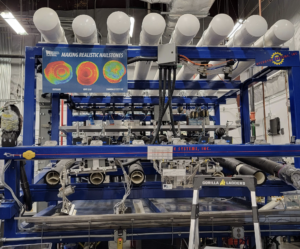

15 years ago, Western Colloid began going to FM Global to start testing on some roof system assemblies. We began with our polyester reinforced all acrylic systems to compete with some of the largest manufacturers in the world. Today Western Colloid has most of our systems/assemblies, accredited under the FM4470 standard at FM Global, which we are very proud of.

Approval is quite a process. You start by being assigned an engineer, designing assemblies, scheduling the build, building them, coming back 28 days later and then doing the destructive

testing to pass with these assemblies. One failed test puts you back to step 1. It says a lot of any company to make the commitment it takes to having that FM approvals mark on your products. If your product has an FM approved mark, that means it’s been through the certification testing process to verify its function as intended.

FM makes required visits to your manufacturing facilities to make sure that we manufacture the exact same products, (along with UL, Miami Dade, and ICC-ES). We have inspectors at our plants to test

the products and make sure the formulas are the same. The re-testing is rigorous with checks on everything from raw material Certificates of Analysis, to testing equipment to checking formulations on every batch.

The FM Diamond approval gives us access to consultants, architects, specifiers, and building owners throughout the United States, and globally. FM Global approval also grants you easier approvals from other agencies. Underwriters Laboratories, (UL), and Miami Dade will accept FM’s results. ICC-ES will also follow FM’s testing, manufacturing process, and certifications.

ICC-ES is a little different. ICC-ES is the International Code Council Evaluation Service formally known as ICBO. They created standards and are responsible for publishing an in-depth book about buildings a

nd structures. Roofing is only a small, although an important, part of it. They create the standards that gets factored into what should be accepted for a flat roof, such as minimum pitch and what materials are acceptable.Most local municipalities, cities, counties, and states create their own building codes, but they don’t always write it themselves. Most go to ICC-ES and refer to their standards.

In the approval process and permitting process, there’s usually a box for the ICC-ES number that they are using. An applicant can just check the box, put the number in, and he’s done. ICC-ES smooths the way for city officials that are approving these projects. They want to know that you’ve spent the money and time to get that number.

ASTM, the American Society for Testing and Materials, is another huge part of this whole process, basically it establishes the codes for most chemistries in world. For example, ASTM standards test your carpet, down to the fiber in the carpet, on strength, materials, performance, or the machines that are used to produce them.

UL (Underwriters Laboratories) is the most recognized source for testing, inspection and certification services in the world. Western Colloid, for example, has UL certification for our Class A fire rating on most products and systems.

CRRC, the Cool Roof Rating Council offers product ratings for companies interested in having their roofing products listed and labeled with information about the products surface radiative performance (solar reflectance and thermal emittance). Any roofing product can be rated as long as it is in compliance with the CRRC-1 Product Rating Program Manual. It is particularly important in California because of Title 24, title 24 in 2005 adopted reflective roofs.

Originally when you mentioned green roofs, sustainability and cool roof systems Energy Star used to be the mark of approval for roofs. CRRC has now stepped in as the authority on that.

Energy Star has now retired their mark of approval, the Energy Star program, for roof coatings. They just didn’t see the value in it currently, but Western Colloid is hoping to change that in the future.

The process you go through with these agency’s total hundreds of thousands of dollars, millions for some companies. This is all to give the building owner a comfort level that the materials/systems they are installing or using have some regulation and testing with a supporting foundation kept in check. Each agency does its part of covering the entire scope of roof systems.

How much should a building owner know about these requirements? This is where consultants and architects come in. They do the deeper dive, so the building owner doesn’t have to. Sometimes the work being performed does not fit into an existing standard or code. That is why it is important to have the approval and ratings backup with FM and UL. We can provide a comfort level that their roof restoration is going to perform, even though it doesn’t match any existing criteria.

The main point with approvals and ratings is it gives the building owner confidence in the quality and the performance of the product. As you can image Western Colloid is very proud of their outstanding testing, approvals, and ratings. The management team has been forefront over the years in getting the roof coatings industry recognized and approved and continues to keep these agencies apprised of new technologies.

We are committed to our ongoing commitment to the approval and testing process. Once you’re in, you’re in for life!

Please contact Western Colloid to learn more about our testing and results.